PRODUCTS

HONOR

QUALIFICATIONS

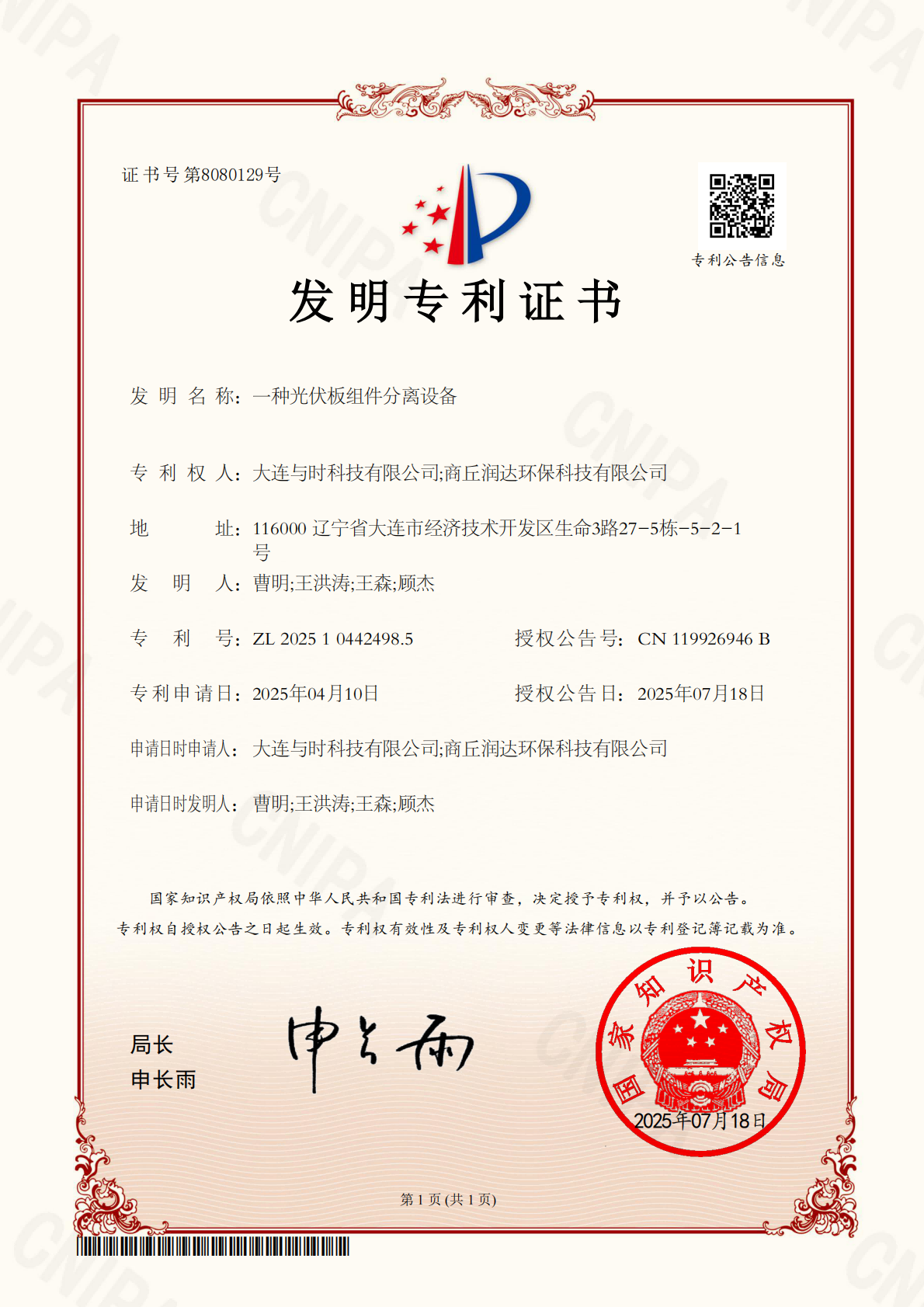

Photovoltaic panel assembly separation device

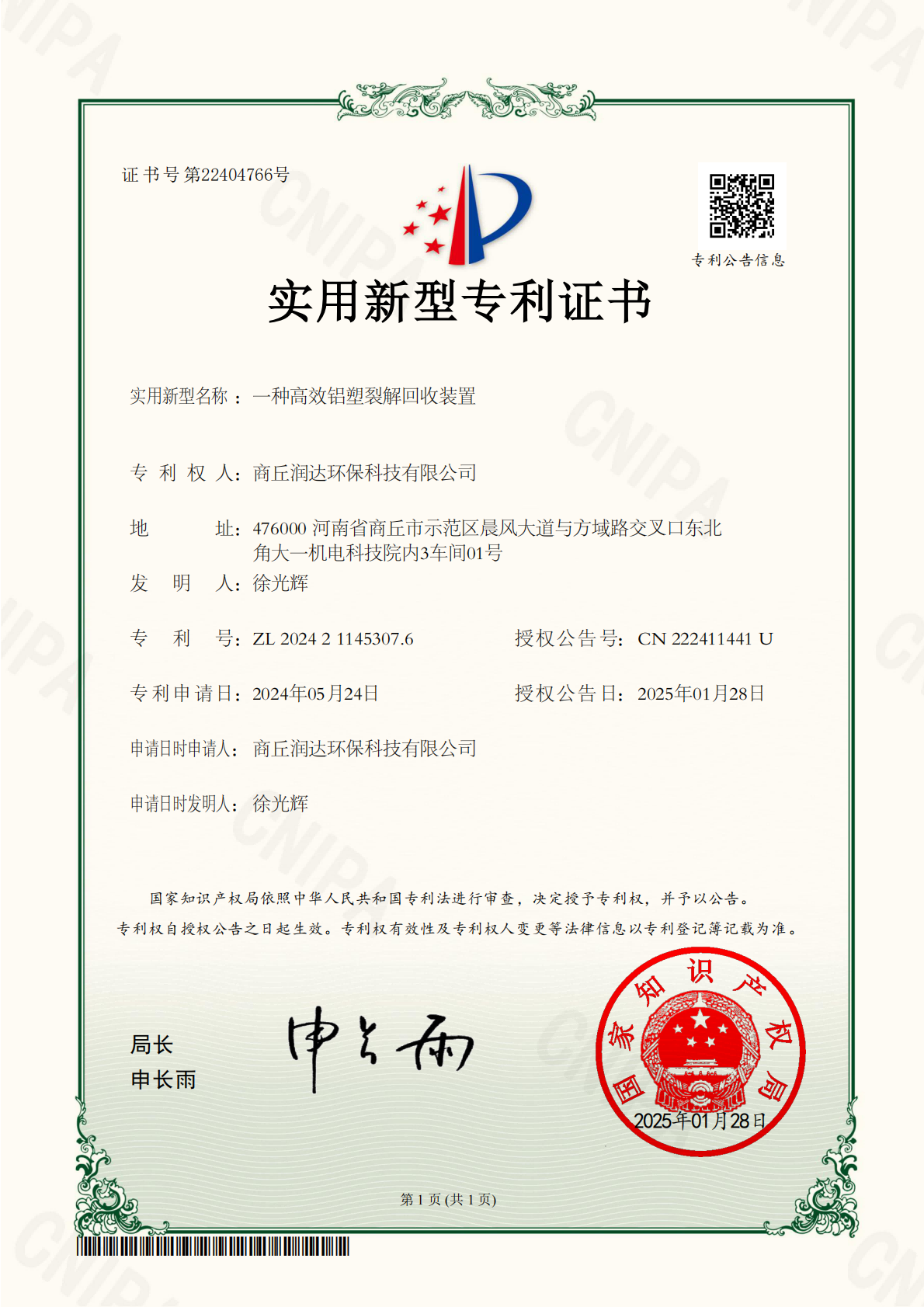

A high-efficiency aluminum-plastic cracking and recovery device

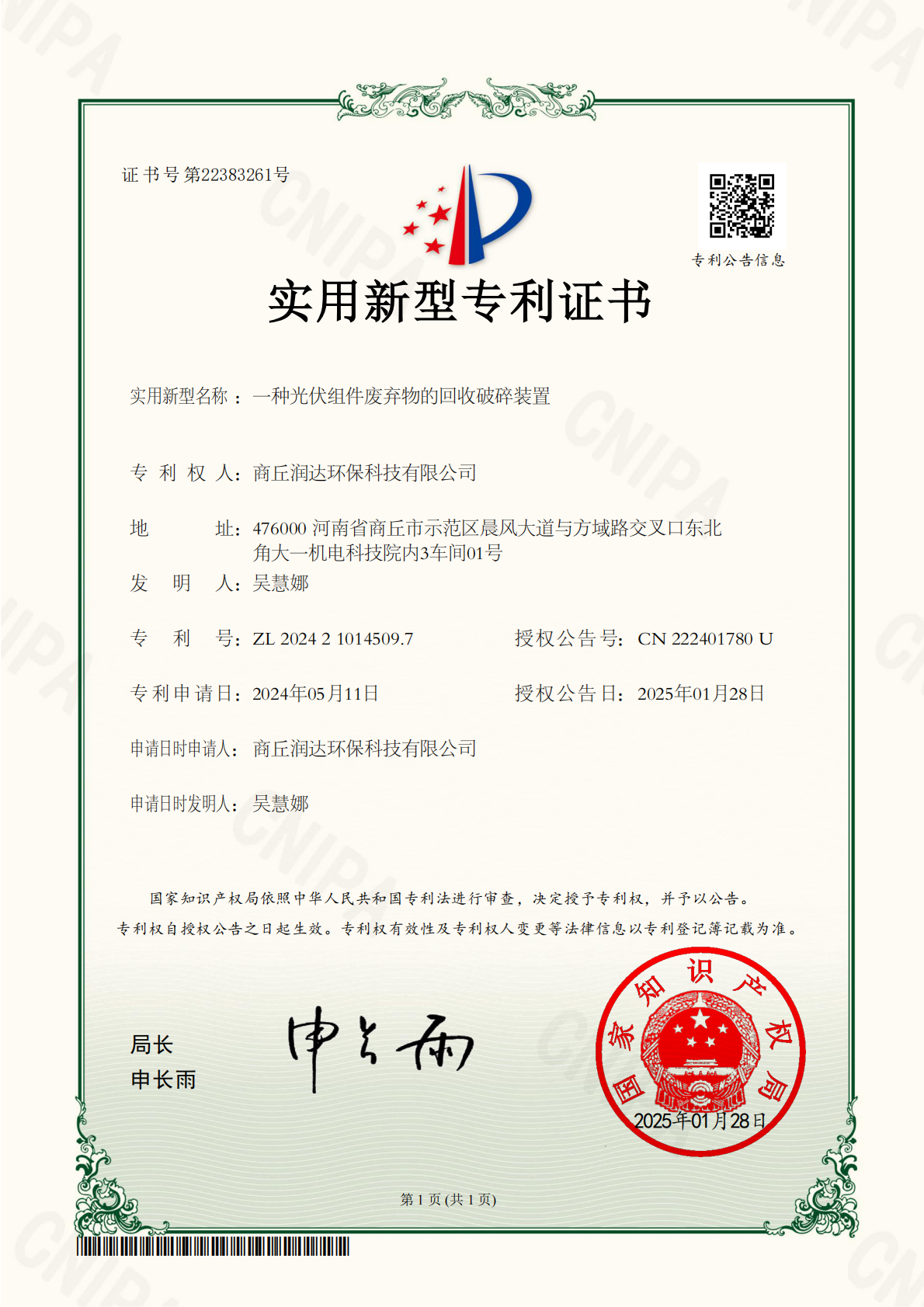

A recycling and crushing device for photovoltaic component waste

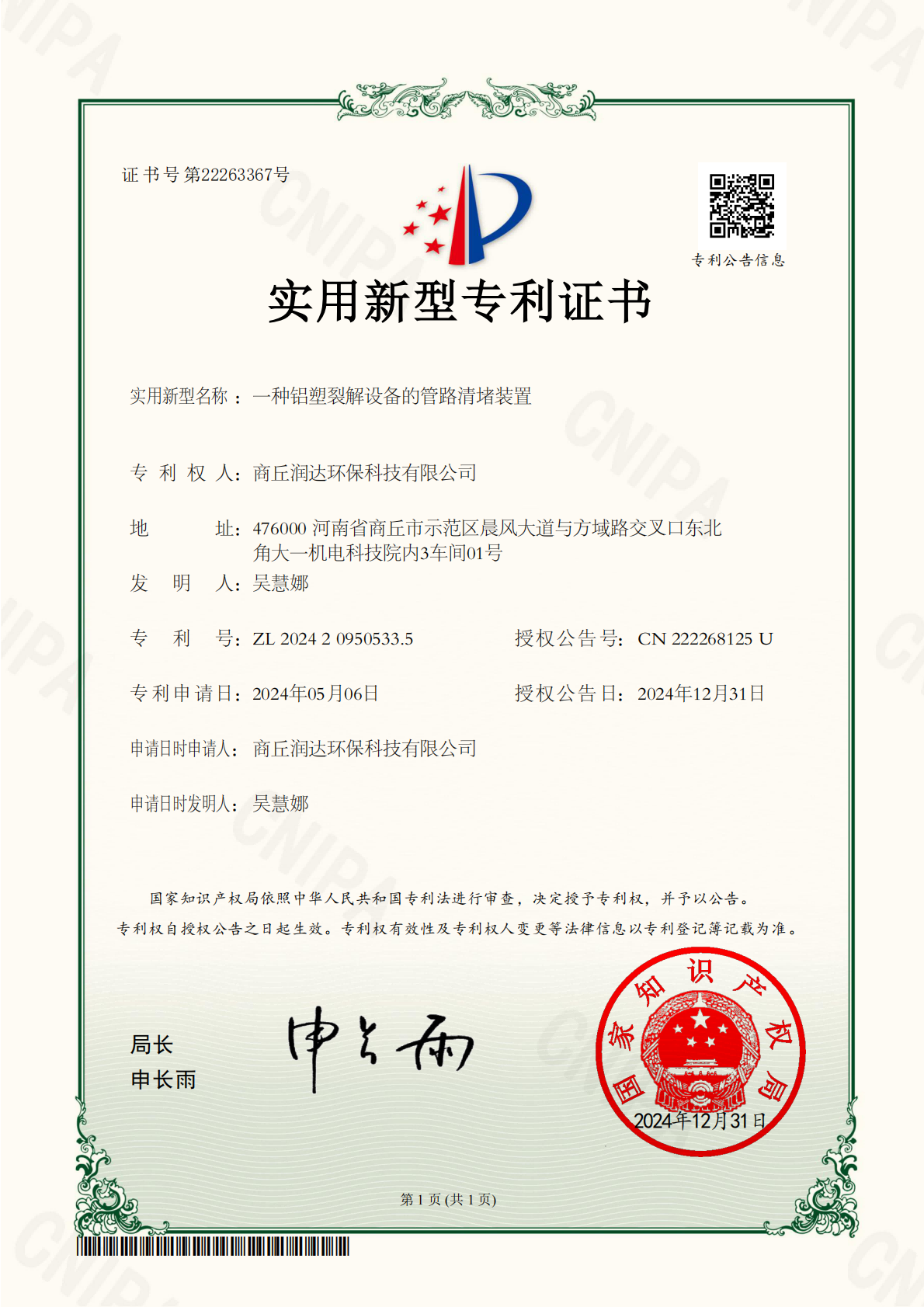

A pipeline clearing device for aluminum-plastic cracking equipment

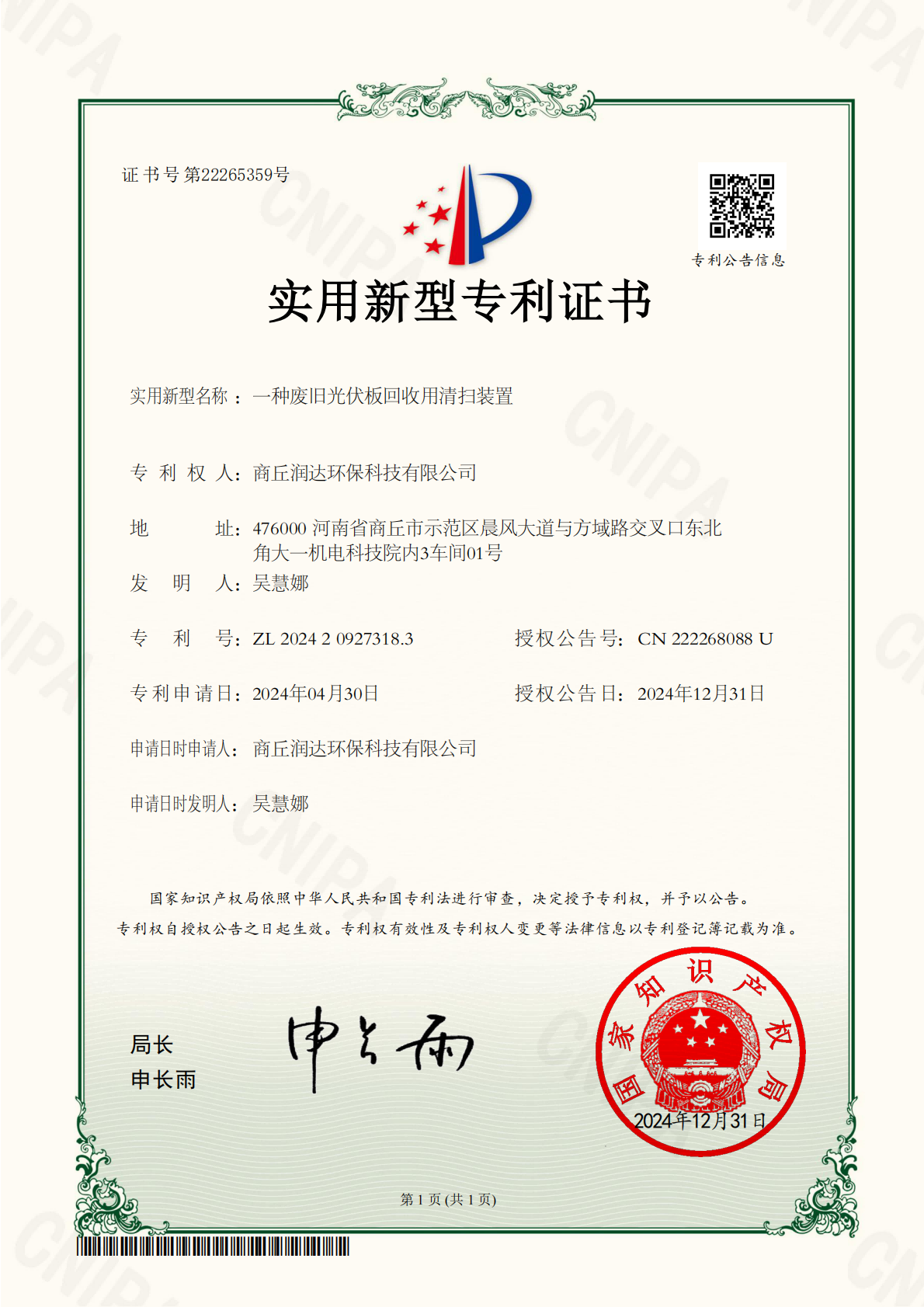

A cleaning device for recycling waste photovoltaic panels

ABOUT US

Shangqiu Runda Environmental Protection Technology Co., Ltd

Shangqiu Runda Environmental Protection Technology Co., Ltd. is a mechanical equipment company that integrates research and development, design, manufacturing, sales, comprehensive technical services, and import and export trade. Since its establishment, we have been focusing on waste pyrolysis and recycling technology, and currently have 18 designers and 35 industry patents. The company takes "green cycle, low-carbon future" as its mission and adheres to the service concept of "technology as the center, quality as the guarantee, customer first, and service first". It can provide targeted customized services for customers of various scales of projects. Including: designing and providing production lines with different processing capabilities according to customer needs; Design and provide different process flows and equipment configurations based on the different raw materials provided by customers and the required final products; You can go to the client's project location and provide drawing design based on the client's existing site. Provide valuable products and technical solutions to customers. At present, Runda equipment has been exported to more than 100 countries including India, Brazil, Thailand, Malaysia, Tanzania, Ethiopia, etc., and is widely used in the global waste pyrolysis and recycling industry, with good economic and environmental benefits. Runda Environmental Protection is committed to making due contributions to the globalization, energy conservation, emission reduction, and integrated development of the energy industry.

Waste solar panel processing plant

Innovative process: Adopting low-temperature anaerobic cracking and molecular flash pyrolysis technology, efficiently converting EVA into fuel oil, and achieving energy self circulation.

High value recycling: precise separation of key materials such as silicon wafers, glass, copper (recovery rate>95%), silver, tin, etc., maximizing value.

Environmental excellence: The entire process is free of wastewater, dust, and dioxin emissions, completely eliminating secondary pollution.

Efficient Economy: Supports large-scale continuous production, no need for pre dismantling glass, strong processing capacity, low operating costs, and considerable profits.

Mature technology: The device design is reasonable, the operation is safe and simple, and the process is stable and reliable.

continuous pyrolysis plant

The continuous cracking equipment developed by Shangqiu Runda Environmental Protection Technology Co., Ltd. has a reaction vessel that rotates externally as a whole and is equipped with a material flipping device inside the reaction vessel. The material is preheated and depolymerized at the front end of the reaction kettle through a feeder, reaching the primary stage of pyrolysis, and then sequentially enters the middle for medium temperature pyrolysis. Carbonization and pyrolysis are completed at the back of the reaction kettle. The slag material (such as carbon black) is discharged and collected through a multi-stage heat exchange slag extractor; The pyrolysis gas is separated from heavy oil and dust by a separator; Cooling oil collection for the cooler; The combustible and non condensable dry gas is purified and sent to the heating furnace as its own fuel for heating; The exhaust gas is further treated by a purification system to meet environmental standards and is discharged.

NEWS CENTER

Real time updates on company news and industry trends, grasping cutting-edge information trends